- TOSIZE.se

Order customised pressed wood varieties online

Order customised pressed wood varieties online

Pressed wood is a versatile form of board material. There are many varieties of pressed wood board material and you will see it in many applications, from attic cupboards to underlayment. In this article you can read all about pressed wood and how to order it easily online.

Already familiar with pressed wood panels and want to continue ordering? Then go to TOSIZE.se, check out our Assortment and order your plate material of choice to size!

What is pressed wood board?

Pressed wood board material is usually called fibreboard. This is because it is made of wood fibres that are glued together and then pressed into a board. This gives it different properties to solid wood and also gives it a different look. With solid wood, and board material using solid wood (plywood and carpentry panels for example), a wood grain is visible. This gives the material a natural look. With fibre boards, there is no wood grain; because wood fibres are pressed together, you can only see the different pieces of wood of which the material consists. Fibreboards are therefore often painted over.

The properties of pressed wood board material vary enormously between the different variants. However, there are a number of properties that each pressed wood board material has, which we have listed briefly:

1. It does not warp

Because pressed wood board material has no wood grain, the material does not warp in the direction of the wood grain. However, the material can deform on contact with heat or moisture, so special variants have been made that are protected against this.

2. It is easy to work with

Due to the construction of fibre boards, the material will splinter less during sawing and milling. As a result, pressed wood board material is easy to work with, making it a good choice for a job with difficult shapes or other complex operations.

3. It is important to treat it well

Since a lot of glue is used when making pressed wood panels, it is important to treat the material well before using it. This protects the material against moisture and makes it last a lot longer!

The variants of pressed wood panels

Pressed wood board material is available in many different variants, such as MDF, Chipboard, OSB, Hardboard or Softboard. Each type has specific properties and different variants. Let us go through them:

MDF

MDF is perhaps the most popular form of board material and in any case the most popular fibreboard. It is made of small wood fibres, the smallest of any fibreboard, which are impregnated with glue and then pressed into a board under high pressure and temperature. This makes MDF very strong, flat and smooth, which makes it popular in furniture and interior design. MDF has a strong absorbing effect and does not withstand moisture well. It is therefore very important to treat the material well. A good priming and lacquering of the top and bottom is recommended. For the ends, you can use an edge sealer. MDF is suitable for dry areas indoors, for use in damp areas indoors you can opt for MDF Moisture resistant V313. MDF Moisture Resistant V313 is made with special waterproof glue and is pressed under higher pressure, which makes it more resistant to moisture than normal MDF. If you wish to use MDF outdoors MDF Exterior a good choice. This material is not only glued with a waterproof glue and pressed under higher pressure, but the wood fibres are also modified to protect the material even better against moisture. Other variants of MDF are MDF fire retardant, MDF Paint Carrier, MDF Black and MDF Ecologique.

Chipboard

Chipboard is made of somewhat coarser wood fibres than what MDF is made of. These wood fibres are also called chips, which is why it gets its name. Chipboard is often used in the manufacture of furniture, but it is often no longer visible as such. In furniture construction, chipboard is often given a plastic top layer. This layer is laminated onto the material and not only provides an attractive finish, but also protects the chipboard from moisture, scratches and impacts. Laminated chipboard The ends of the board must still be treated, but this can be done using an edge sealer. Other variants of chipboard are V313 Moisture-resistant chipboard and Rough chipboard.

OSB

OSB is a board material made of coarse wood chips that are glued and pressed into a board. The wood chips are first sorted lengthwise, which is how it got its name: OSB (Oriented Strand Board). The material is mainly used in construction because it is very strong. Its rough appearance means that it is not often used for cosmetic work or furniture. With today's growing industrial trends, this is changing and you are increasingly seeing furniture made from OSB. OSB is not available in different varieties, but there are four different strength classes, where class 1 is the least strong and class 4 the strongest. Class 4 is not easy to obtain in the Netherlands and is mainly sold in countries where there are specific building requirements. The strongest variant of OSB available in many places in the Netherlands comes under class 3 and is referred to as 'OSB3'.

Hardboard

Hardboard is a thin board material made without the addition of glue, instead water is used. It is pressed under high pressure and temperature into a thin plate. Hardboard cannot be used for constructional applications and cannot come into contact with moisture. It is often used for back walls of, for example, cupboards.

Softboard

Softboard, like Hardboard, is made by mixing wood fibres with water and pressing it under pressure and high temperature to form a board. With softboard, less pressure is applied during the pressing, so that the end result is softer. Softboard is applied as an insulation material for warmth, sound and light in, among other things, partition walls and underfloors.

Made-to-measure pressed wood

Pressed wood panels are often sawn to size before you use them. A sawmill can cut the board to size for you; at TOSIZE.se this can even be done in different shapes and sizes and, of course, to the millimetre. These are the options:

Sawing in different shapes

Fibreboard is produced in large sheets, which is why it is often necessary to saw the sheets to size. This can be done at TOSIZE.se in various forms:

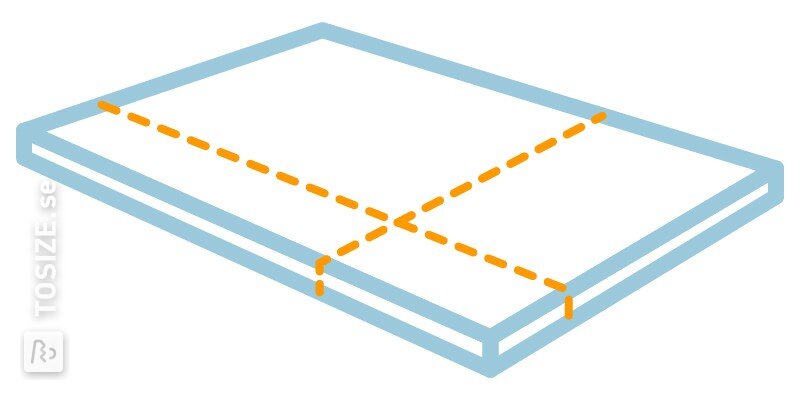

Rectangle

Rectangular shaped fibreboards can be used in many different ways. In the construction industry, for example, they are used in partitions and underlayment, but rectangular fibreboards are also used for tabletops and kitchens, among other things.

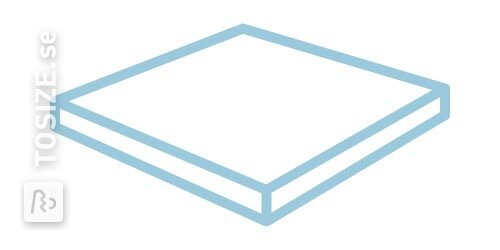

Square

Square-sawn board material comes in a close second. Besides the applications that rectangular board material can be used for, square board material can also be used for, for example, crates and floor tiles.

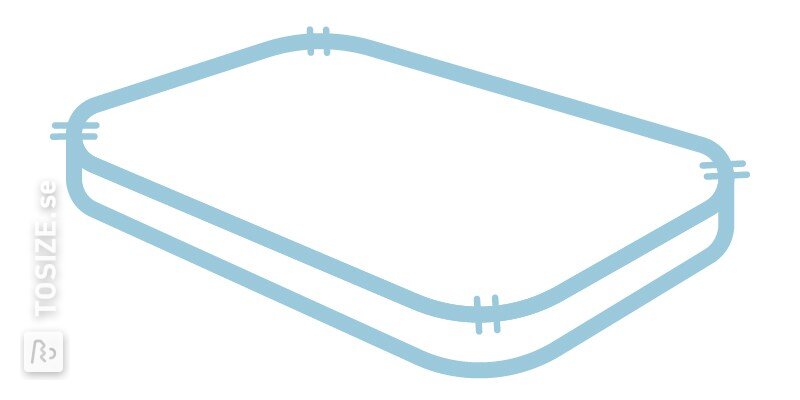

Rounding or chamfering corners

When you cut squares or rectangles from fibreboard, the corners can be very sharp. To make the corners less sharp, they can be bevelled or rounded. This can be done for two corners or for all corners.

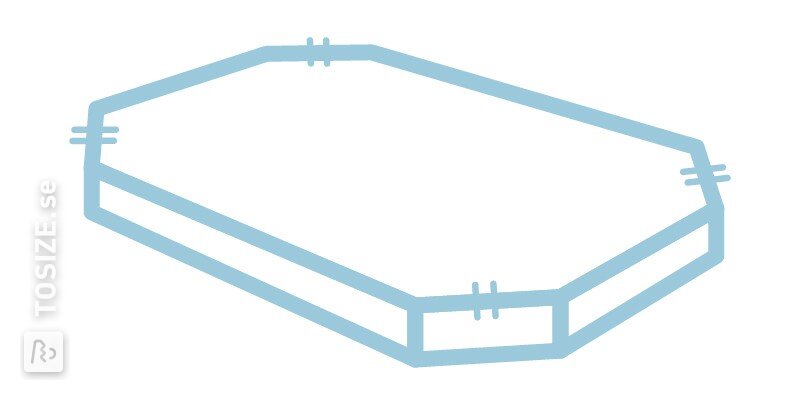

Chamfering edges

For rectangles, it is possible to bevel one side of the sheet material. This can be done for a long side or a short side.

Triangles

There are three options to choose from when it comes to sheet material in the shape of a triangle. First of all, you can have a regular triangle sawn to size; with this triangle you can determine the dimensions and the position of the top corner yourself. Next, you can choose a rectangular triangle; here too you determine the dimensions yourself, but the top corner will be on the side of the material. Finally, you can also choose a symmetrical triangle. This shape has the top corner in the middle of the length.

Circles

We use advanced sawing machines to saw round sheet material at TOSIZE.se. This means that the circle is not only cut to the millimetre, but also without a hole in the middle! You can also have us saw a semicircle to size.

Trapezium

A trapezium resembles a triangle from which the top point has been sawn off. The end result is a rectangle where the short sides run diagonally inwards or outwards. These sheets are often used as joints.

Parallellogram

The short sides of a parallelogram run diagonally. The short sides of a parallelogram run diagonally. The shape is often used when creating larger work surfaces.

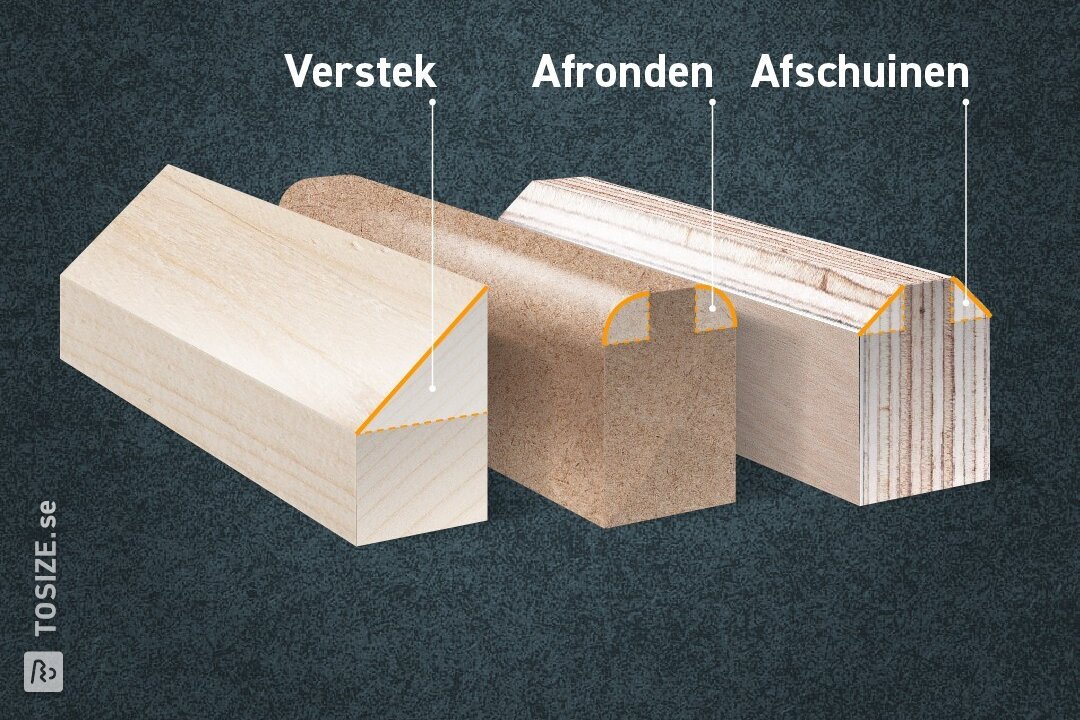

Finishing of the end edges

For certain constructional and decorative applications, it is useful to have the ends of pressed wood panels finished. At TOSIZE.se you can choose from different finishes, the size of which you can determine yourself. In this way, we make the job even easier for you.

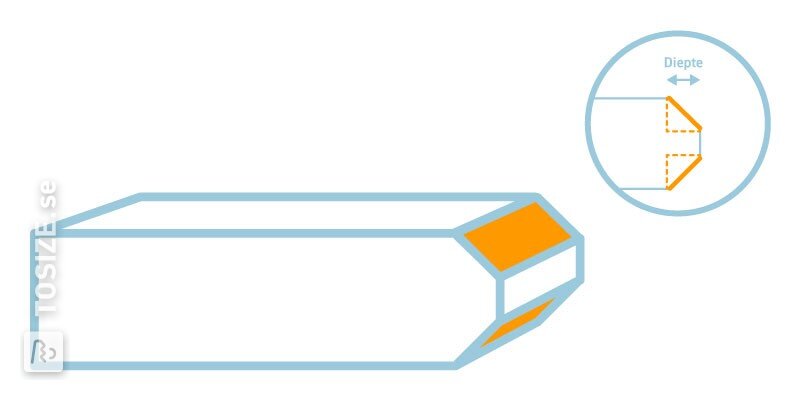

Mitre

To make a beautiful invisible connection of board material, especially fibre boards, you need to saw mitred board material. As standard, we saw the end edges diagonally at an angle of 45°, but you can also determine the angle yourself.

Rounding

Rounding off the end edges ensures less sharp edges and a better finished end result. Rounding can be done for the top and bottom, and also for both sides.

Chamfer

Naast het afronden van de kopse kanten, kun je de kopse kanten ook laten afschuinen. Dit geeft de plaat een strakke en moderne uitstraling. Ook hier kun je kiezen voor het afschuinen van de bovenkant, onderkant of beide kanten.

Hollow section

A hollow profile is made by hollowing out the corners of the end faces. This makes the middle of the end stand out, which gives a playful effect.

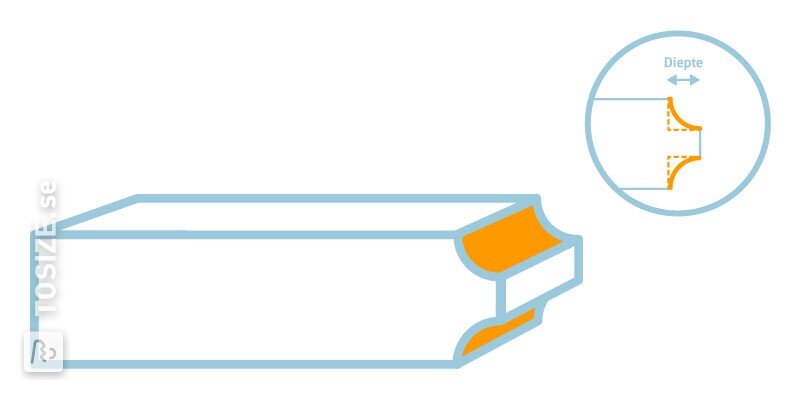

Quadrant

A quarter round finish is often seen in classic mouldings. The curves give it a timeless look and make it a good fit for projects in a classic or country style.

Ordering pressed wood panels to size

Order pressed wood panels easily and quickly at TOSIZE.se, see our Assortment for the current range of fibreboards. Once you have selected the desired material, you can easily choose the size, shape and finish. Once the order has been completed, we will start working for you immediately! Start ordering now and take the first step towards your new job!