- TOSIZE.se

- Material properties

Discover different types of grain patterns for unique wooden furniture pieces

Discover different types of grain patterns for unique wooden furniture pieces

Wood is one of the most versatile and durable materials used in the construction and furniture industries. Apart from the type of wood, there are a number of important aspects to consider when choosing wood veneered board materials. In this article, we explain more about the wood grain, which is mainly determined by the cutting method and jointing technique.

If you are looking for high-quality wooden furniture or building materials, understanding different wood designs is essential. This is because the wood drawings determine the look and texture of the wood. If you want a specific wood drawing, then two details are important: The cutting method and the jointing technique. In this article, we will simply explain what to look out for. We will discuss the main types of cutting method that affect the wood pattern: dosse fineer, kwartiers fineer, half quartered, mix, head and print veneer. We will also explain a few things about jointing techniques. At the bottom of the page you will find several examples of wood designs with jointing techniques. This way, you can discover the best choice for your next project!

Cutting method

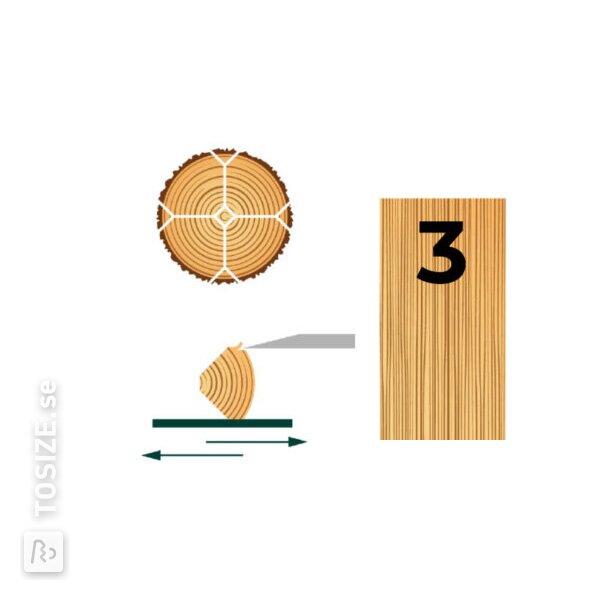

Crown / plain cut veneer (1)

Crown / plain cut veneer is one of the most common wood designs and is characterised by long, wavy patterns in the wood. It is known for its unique and rustic appearance. It is achieved by sawing a tree trunk along its length into slices, creating beautiful, long and wavy patterns in the wood. Crown / plain cut veneer brings out the natural beauty of the wood and is often appreciated for its rustic look.

What is special about dosse fineer is the way it retains the characteristic patterns and texture of wood. The wavy lines and knots in the wood give dosse fineer a distinctive and rustic charm, making it an excellent choice for projects pursuing a natural look. It is often used for floors, cabinets and furniture with a traditional or rustic aesthetic.

For lovers of the rustic beauty of wood, burr veneer is an excellent choice. It brings the warmth and natural charm of wood to any project and adds a touch of authentic elegance to interiors and furniture pieces. With dosse fineer, woodworkers and designers can capture the timeless appeal of nature in their creations.

Kwartiers fineer

Kwartiers fineer is obtained by cutting a tree trunk into four quarters, with the wood coming directly from the heartwood of the tree. This creates a wood pattern with straight lines and an even structure. It is a popular choice in the veneer world because of its distinctive straight lines and even texture. It is often used for high-quality furniture, cabinets and interior decoration. There are two main variants of kwartier fineer: quarter normal cut and quarter rift cut. Here are the main differences between these two cutting methods:

Kwartier vals (normal cut) (3)

Cutting at right angles to the annual rings creates very nice straight-grained markings. Properties of normal cut are:

-

Straight lines: In quarter normal cut, the wood veneer is cut along the length of the log, perpendicular to the growth rings. This results in veneer sheets with straight lines parallel to the longitudinal direction of the wood.

-

Even structure: This cutting method offers a very even texture with regular patterns. The veneer has a consistent appearance and uniform texture, making it ideal for furniture and interior finishes that aim for a symmetrical and balanced appearance.

-

Less noticeable markings: While quarter normal cut veneer is beautiful, it often has less noticeable markings compared to quarter rift cut. It is more subdued and suitable for projects where the emphasis is on a clean and uniform appearance.

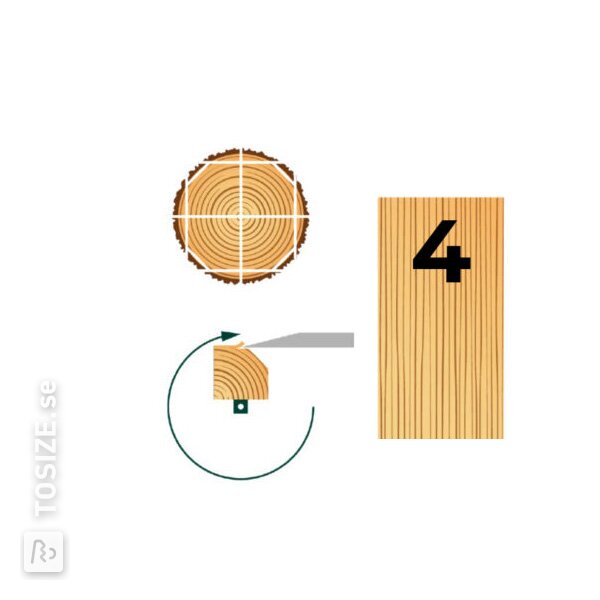

Quarter cut (rift cut) (4)

The tree rotates around its axis and cuts are made at certain angles perpendicular to the annual rings. This creates a straight-edged drawing with very even lines. Features of rift cut are:

-

Diagonal lines: Quarter rift cut veneer is cut at an angle of about 30 to 60 degrees to the growth rings of the tree trunk. This creates diagonal lines in the veneer, forming a distinctive and striking pattern.

-

More complex texture: The cutting method of quartered rift cut results in a more complex texture with a characteristic flame-like or radial pattern. This gives the veneer a unique look that is often considered more visually appealing than quartz normal cut.

-

Particularly suitable for oak: Quarter rift cut is often applied to oak because of the beautiful markings it produces. It is appreciated for its striking visual effects and is often used in furniture designs where the veneer is used as a prominent decorative element.

Half kwartier

Half kwartier veneer is a veneer technique that is midway between deadweight and kwartiers fineer. It is obtained by cutting a tree trunk into two halves, with the wood coming directly from the heartwood of the tree, but with a slight variation. These subtly less straight lines and slightly looser texture give Half kwartier quartered veneer a distinctive look that is both natural and attractive.

One of the remarkable features of half kwartier veneer is the balance it offers between the natural knots and lines of dosse fineer and the tight symmetry of kwartiers fineer. This creates a fine balance between character and stability in the veneer.

For those seeking a wooden project with a subtle, yet characterful look, half kwartier fveneer is an excellent choice. It offers a balanced combination of natural beauty and stability, giving furniture and interiors an attractive and durable look. Half kwartier veneer adds a touch of warmth and personality to wooden projects, making them stand out in their simplicity and elegance.

Mixed veneer

Mix veneer is a particularly exciting veneer technique that brings together the diversity of wood species and patterns in one surface. This type of veneer is created by combining different parts of the tree trunk, such as dosse, quartered, half-quartered and other veneer sections. The result is a unique veneer with a varied appearance, consisting of a combination of straight lines and wavy patterns.

One of the striking features of mix veneer is its ability to exploit the visual appeal of various wood species. This allows designers and woodworkers to create surfaces that incorporate both traditional and contemporary style elements.

Mix veneer offers endless creative possibilities in woodworking. It allows you to design unique and artistic surfaces that stand out from standard veneer patterns. This makes it a valued choice for modern furniture, flooring and interior decoration where originality and personality are paramount.

For those who aim to add artistic flair and diversity to their wooden projects, mix veneer is a fascinating option. It allows you to merge the rich texture and patterns of different woods into a visually captivating whole. Mix veneer is an excellent way to explore your creativity in woodworking and create unique, custom-made pieces that attract attention and garner admiration.

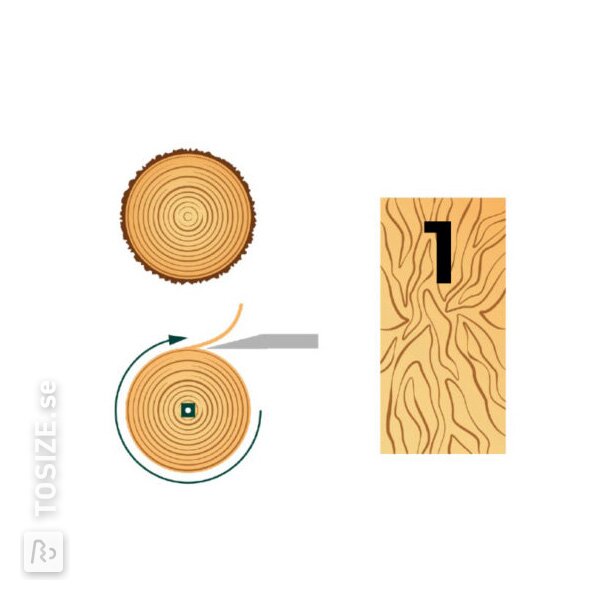

Roll-off veneer (1)

Roll-off veneer is a notable technique in the world of veneers because of its focus on durability and efficiency. In this method, thin layers of veneer are cut from a tree trunk with minimal waste of wood. This makes roll-off veneer an eco-friendly option for veneer production.

The veneer is machine-cut from the tree trunk, obtaining thin layers using a rotating drum. This technique minimises the amount of wood wasted during the cutting process, as the veneer is "unwound" from the log. This makes more efficient use of precious wood resources.

Roll-off veneers are especially beneficial when working with large trees, where traditional veneering techniques often waste more wood. Moreover, the veneer produced by roll-off techniques is of high quality, with a smooth and consistent texture. This makes it suitable for a wide range of applications, from furniture to interior decoration.

In the world of woodworking, roll-off veneer is a valuable choice for those who strive for both aesthetic perfection and environmental awareness. It offers not only an efficient way to produce veneers, but also a sustainable alternative to traditional veneering techniques. With roll-off veneer, designers and woodworkers can create beautiful wooden surfaces while keeping the environment in mind.

End grain veneer

End grain veneer is a veneer technique characterised by a pattern of concentric circles, obtained by cutting a tree trunk transverse to the growth rings. This unique cutting process highlights the circular patterns in the wood and results in veneers with a striking and intriguing visual appearance.

One of the most striking features of End grain veneer is its emphasis on the tree's natural growth rings. These rings give the veneer a distinctive and organic appearance, making it highly desirable for turnings, carvings and ornaments. End grain veneer is often used to highlight circular patterns in wood, resulting in beautiful tabletops, panels and works of art.

End grain veneer allows designers and woodworkers to create surfaces that attract attention and have a sense of movement and depth. It is a popular choice for those striving for a unique and artistic look in their wooden projects. End grain veneer embodies craftsmanship and the beauty of wood's natural growth, making it a valuable addition to any creative woodworking project.

Print veneer

Print veneer represents an exciting innovation in the world of woodworking. This technique involves applying thin layers of wood veneer to a wooden surface using advanced technologies. The results are amazing: designers and furniture makers can create unique patterns, images and textures on the surface of wooden furniture pieces and decorative elements.

One of the striking features of print veneer is the unlimited creative freedom it offers. With print veneer, you can transfer any design or pattern you want onto wood, from intricate illustrations to lifelike images. This opens the door to endless possibilities for personalising furniture and decoration with an artistic touch.

Print veneer is particularly suitable for projects where originality and individuality are paramount. It allows you to create furniture and interior decoration that tells a story, evokes an atmosphere and reflects the owner's personality. This technique makes woodworking an art form that pushes the boundaries of creativity and creates unique, custom-made pieces that spark the imagination.

Joint techniques

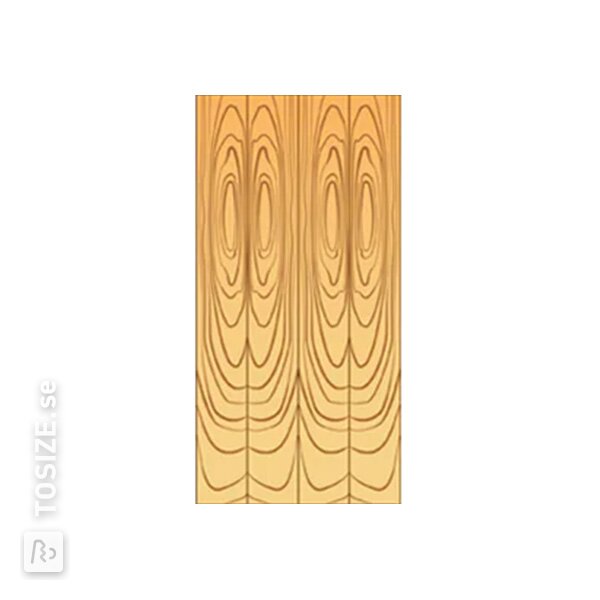

Book joints

Book jointing, also known as bookmatch, is a jointing technique in which two veneer sheets are opened like a book. This is the standard jointing method. The cut strips of veneer are jointed two by two mirrored to each other. Through this technique, the image change of the tree is clearly visible in the jointed sheet. This creates a symmetrical pattern that resembles an opened book. This technique is often used for veneer tops with striking natural patterns, creating a harmonious and symmetrical look.

Slid joints

Slid joints, also known as slipmatch, involve placing the veneer sheets in the same direction but with a slight offset, so that the pattern continues continuously without interruption. The veneer strips are slid one after the other and jointed together. This is the recommended jointing technique if the veneer is to be coloured. Because all strips lie with the same side up, there is no colour difference between them. This technique is perfect for veneers with linear patterns, such as oak or walnut, and creates a sleek and uniform appearance.

Twisted joints

Twisted slipped jointing, also known as alternating slipmatch, is a variation of the slipped jointing technique. Here, the veneer sheets are placed in the same direction, but with every other sheet turned a quarter turn. The head-to-foot combination ensures that the veneer is spread more evenly over the entire sheet. This gives a more playful pattern with a subtle variation in the lines and is popular for contemporary and modern designs.

Mixmatch joints

Mixmatch joint is a creative grouting technique where veneers with different patterns and colours are combined to create a unique look. Mixmatch literally means "mix and match". The veneer strips are joined together randomly, with variation in colour and texture, but still form a matching whole. Mixmatch is the veneer alternative to the plank effect of solid. It is possible to create a mix of both planks and quarters, or of only planks or quarters. This gives designers the freedom to create artistic and striking surfaces and exploit the visual appeal of different wood species.

Mirror joints

Mirror joints, also known as book and butt match, are similar to book joints, but with a twist. Two sheets are opened like a book, and two other sheets are placed side by side with the patterns mirrored. This creates a contrasting effect that is visually interesting and often used for luxury veneer surfaces.

Balance matched joints

Balance matched joints, also known as centre balance match, involve matching the centre of each veneer leaf, creating a balanced pattern. This is ideal for veneers with pronounced knots or distinctive patterns in the centre, emphasising the centre of the design.

Examples

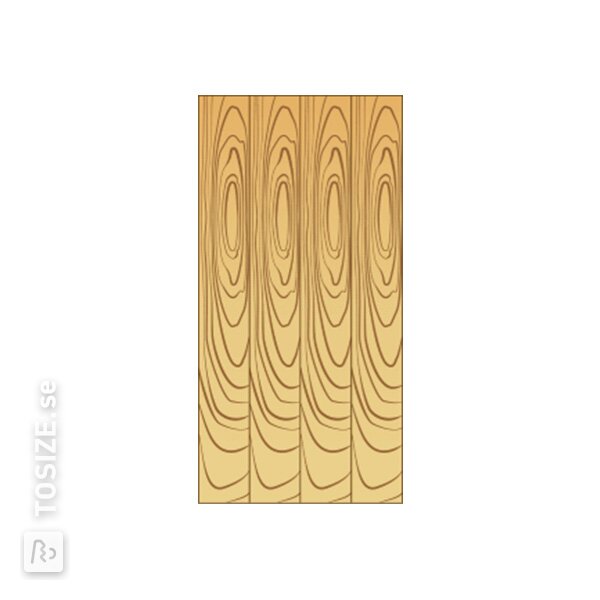

Dosse

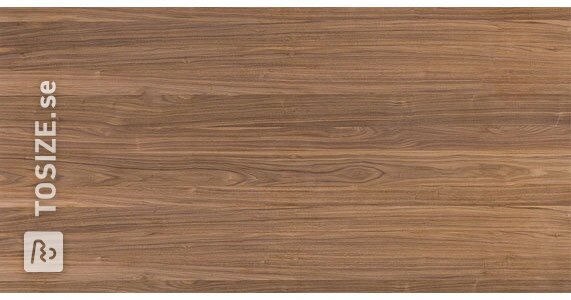

Wood Type: Walnuts American

Cutting method: Dosse

Type of joint: Book

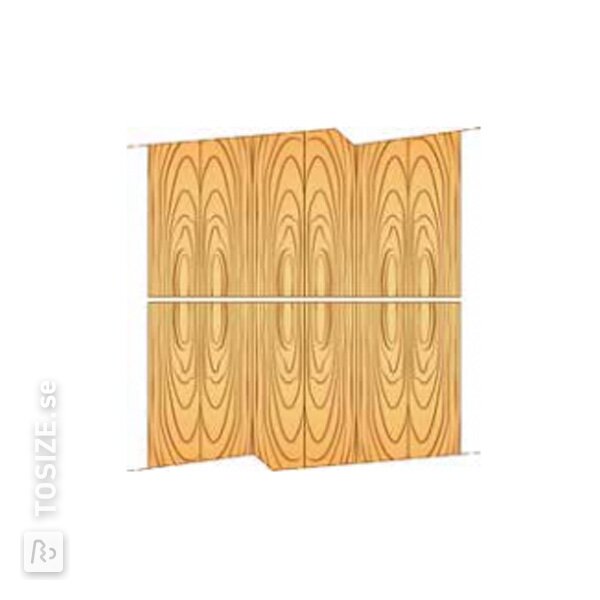

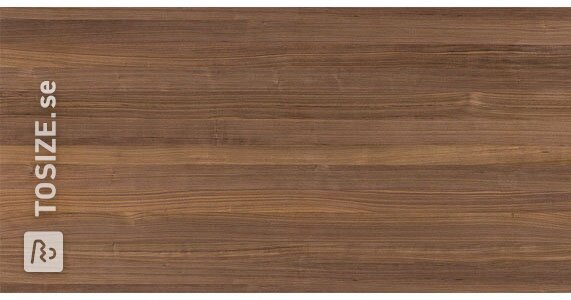

Wood Type: Walnuts American

Cutting method: Dosse

Type of joint: Slid

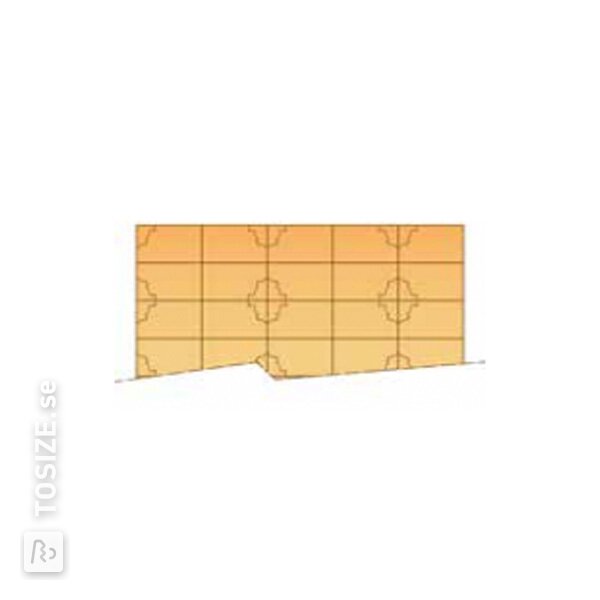

Wood Type: Walnuts American

Cutting method: Dosse

Type of joint: Twisted slid

Mixmatch

Wood Type: Walnuts American

Cutting method: Dosse

Type of joint: Mixmatch

Wood Type: Walnuts American

Cutting method: Mix

Type of joint: Mixmatch

Wood Type: Walnuts American

Cutting method: Quarter

Type of joint: Mixmatch

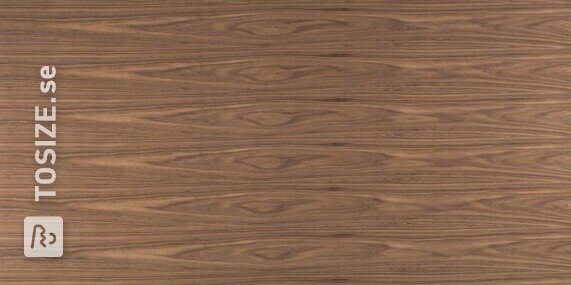

Wood with its own character

Understanding the different types of wood designs and jointing techniques is fine when selecting the right wood for your projects. Whether you're looking for a rustic look with dosse fineer, an even texture with quarter veneer, a distinctive look with half-quarter, a patterned look with End grain veneer, or a varied look with mix veneer, or a contemporary look with print veneer, the choice of wood design will determine the final look of your furniture or building project. And, whether you aim for symmetry with book joints, a uniform look with slid joints, a playful twist with twisted slid joints, artistic freedom with mixmatch joints, visual contrasts with mirror joints, or balance with balance matched joints, veneers offer endless possibilities for embellishing furniture, cabinets, and other wooden creations. Choose wisely and create beautiful, unique pieces that will stand the test of time.

Photos & Illustrations © Decospan