Create your own tool wall

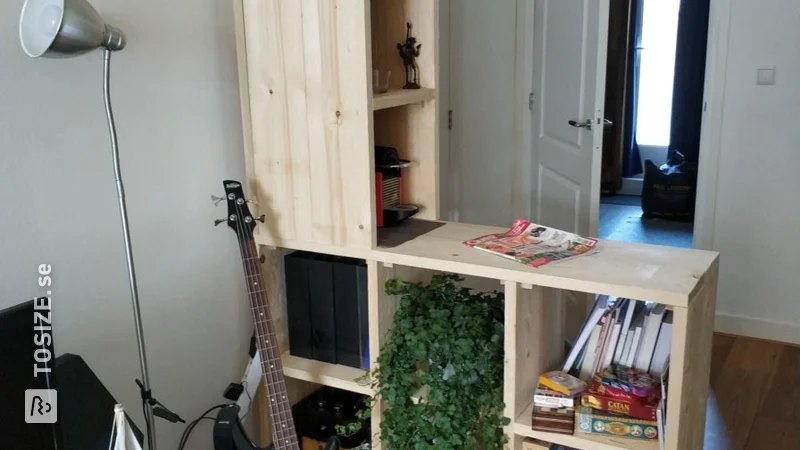

A tool wall brings order to the workspace or the shed. You hang your most important tools on it and everything has a fixed place. This way, you create structure and you don't have to search for tools during your job. This saves time and aggravation. Are you making the tool wall yourself? Then you can adapt the design to your tools. This is how you get started:

Step 1: The design

If you have different tools at home, you probably also have experience with DIY. That is a good start! However, even if you don't have much DIY experience, a tool wall is a great job to do. You can make it as complicated as you like. Decide, based on your tools, what the tool wall should look like. If necessary, get online inspiration for a nice design and give it your own twist. Make a sketch and determine the dimensions of the tool wall that you want to make.

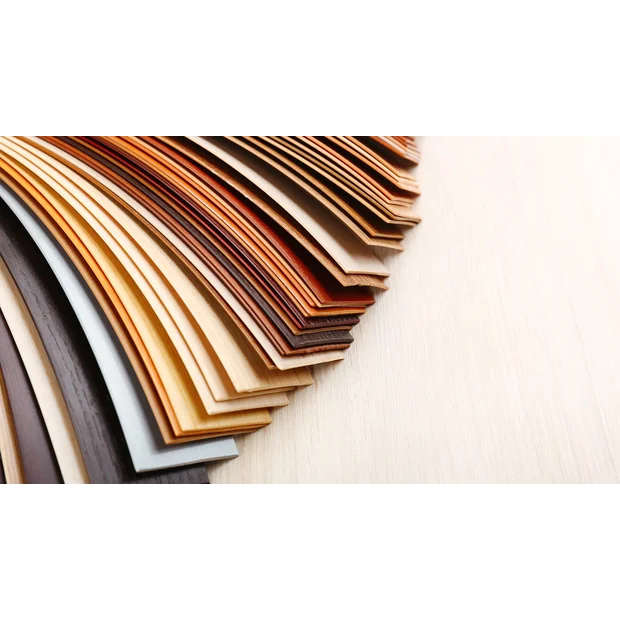

In the past, people often chose pegboard; a sheet material with all those pre-drilled holes. However, this is not the only possibility for making a tool wall. Make it for example from OSB or MDF and choose a frame with hooks, eyes and trays; this way you will have a unique result!

OSB

OSB is a structurally strong board that is widely used as a construction board, for example for floors, walls, roof elements, wall cladding and temporary fencing or panelling. Due to its industrial appearance, OSB is also increasingly used for decorative applications such as furniture, kitchens and table tops. OSB 3 has moisture-resistant properties. OSB is also a sustainable product as it is made from wood chips which would otherwise be waste.

MDF

MDF is one of the most popular types of board material. It can be used for countless projects. MDF belongs to the family of fibreboards; the board consists of wood fibres that are compressed under high pressure. This makes the material easy to process. MDF is available in different variants: MDF Clear, MDF Paintable, MDF Moisture Resistant V313, MDF Waterproof and MDF Black.

Want to know more about MDF? Watch our product video here.

Scaffoldwood

Scaffold wood boards have a robust appearance and can be used for indoor and outdoor projects. Furniture such as beds, tables, cupboards and shelves are often made of scaffolding boards. But also wall covering is a nice idea for a tough look! The planks are new (so not used in construction, which means there are no nails in the planks) and made of rough (unplaned) pinewood, which gives the planks their robust appearance.

Underlayment

Underlayment is a structural board that is primarily used as a subfloor. This is where it gets its name. But in the meantime the board is used for many more applications. Think, for example, of walls and roofs. Because of its very natural appearance, the material is also used for decorative applications such as furniture and worktops.

Want to know more about underlayment? Watch our product video here.

Chipboard

Chipboard can be used both as a constructional and decorative board. It is easy to process and, like MDF and OSB, belongs to the family of fibreboards. Chipboard natural is made of glued wood chips that are pressed together in three crosswise layers. This makes the board structurally strong. In comparison to MDF, coarser chips are used and in comparison to OSB, finer chips are used. Because a waste product (the wood chips) is used, chipboard is a sustainable product and relatively affordable.

Step 3: Material sawn to size

At TOSIZE.se you can order the material of your preference directly to size. This way, you don't need to bring out the saws, but can pay more attention to the design or finish of the tool wall. We also saw in shapes and we can take care of edge finishes. Curious about the possibilities? Take a look at the shapes and edge finishes here.

Order your made-to-measure sheet material!

Step 4: Adding accessories

Did you know that you can also order accessories at TOSIZE.se? For a tool wall, screws and various hooks are useful. If you order everything at once, you will receive it as a kit. Ideal, right?